Introduction to Refrigeration Compressor:

Definition:

- A refrigeration compressor is a mechanical device that compresses refrigerant vapor from a low-pressure, low-temperature state to a high-pressure, high-temperature state.

Purpose:

- The primary purpose of the compressor is to maintain the circulation of refrigerant within the refrigeration system, facilitating the transfer of heat from one area to another.

Types of Refrigeration Compressors:

Reciprocating Compressors:

- These compressors use a piston-cylinder arrangement to compress the refrigerant. The piston moves up and down within the cylinder, creating a vacuum to draw in refrigerant vapor and then compressing it.

Rotary Compressors:

- Rotary compressors use a rotating mechanism, such as a scroll, rotary vane, or rotary screw, to compress the refrigerant. They are known for their compact size and quiet operation.

Centrifugal Compressors:

- Centrifugal compressors utilize centrifugal force to compress the refrigerant. They are commonly used in large-scale industrial refrigeration systems due to their high capacity and efficiency.

Working Principle of a Refrigeration Compressor:

- Compression: The compressor takes in low-pressure refrigerant vapor from the evaporator and compresses it, raising its pressure and temperature. This compressed vapor is then discharged from the compressor.

- Circulation: The high-pressure, high-temperature refrigerant vapor is circulated through the condenser, where it releases heat to the surroundings and condenses into a liquid state.

- Expansion: The liquid refrigerant passes through an expansion valve or capillary tube, where its pressure and temperature drop significantly as it expands into the evaporator.

- Evaporation: In the evaporator, the low-pressure, low-temperature liquid refrigerant absorbs heat from the surroundings, causing it to evaporate into a vapor again. This cycle repeats continuously to maintain the desired temperature inside the refrigerated space.

Components and Features of a Refrigeration Compressor:

Motor:

- The compressor is typically powered by an electric motor, which drives the compression mechanism.

Compression Mechanism:

- This includes components such as pistons, cylinders, scrolls, vanes, or screws, depending on the type of compressor.

Lubrication System:

- Compressors require lubrication to reduce friction and wear between moving parts. Lubricant is circulated through the compressor to ensure smooth operation.

Cooling System:

- Some compressors feature built-in cooling mechanisms, such as internal fans or external fins, to dissipate heat generated during compression.

Control System:

- Modern compressors may incorporate advanced control systems to regulate compression capacity, monitor operating conditions, and optimize energy efficiency.

Applications of Refrigeration Compressors:

- Refrigeration compressors are used in various applications, including residential refrigerators, commercial refrigeration systems (such as walk-in coolers and freezers), air conditioning systems, industrial refrigeration plants, and transportation refrigeration (such as refrigerated trucks and containers).

Here are some well-known compressor brands that manufacture units suitable for both Freon (refrigerants such as R-134a, R-404A, R-410A) and ammonia (R-717):

Compressors for Freon:

- Copeland: Copeland compressors, manufactured by Emerson, are widely used in commercial and residential refrigeration systems. They offer a range of scroll, reciprocating, and semi-hermetic compressors suitable for various applications.

- Danfoss: Danfoss produces compressors for both commercial and industrial refrigeration applications. Their range includes hermetic, scroll, and semi-hermetic compressors designed to work with different types of refrigerants.

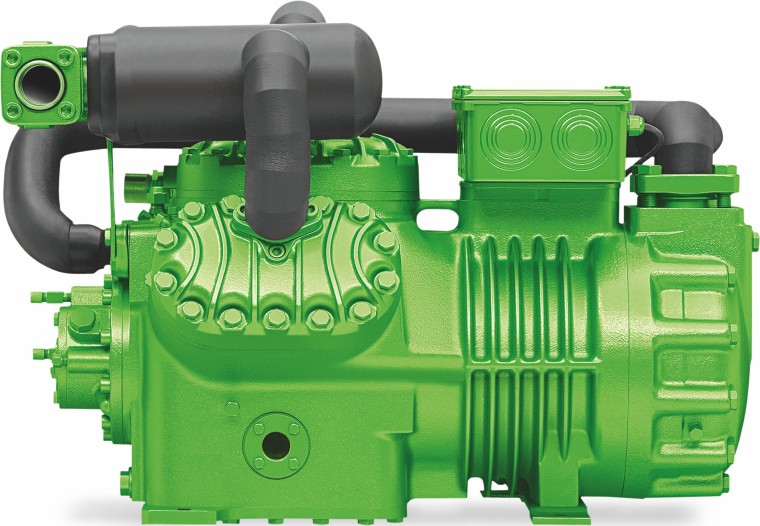

- Bitzer: Bitzer is a leading manufacturer of refrigeration compressors known for their reliability and efficiency. They offer a wide range of reciprocating, screw, and scroll compressors suitable for Freon-based refrigeration systems.

Compressors for Ammonia:

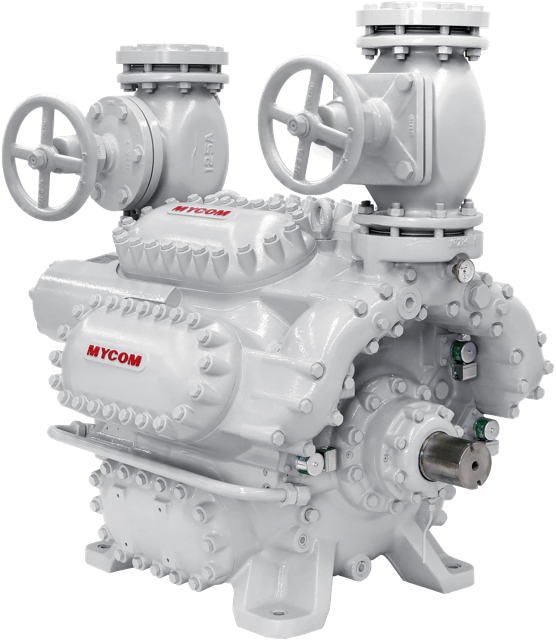

- Mycom: Mycom, a subsidiary of Mayekawa, specializes in industrial refrigeration systems, particularly those using natural refrigerants like ammonia. They manufacture screw compressors designed for high-efficiency ammonia-based refrigeration systems.

- GEA: GEA is another major player in the industrial refrigeration market, offering a range of screw and piston compressors suitable for ammonia refrigeration systems. Their compressors are known for their robust design and high performance.

- Grasso: Grasso, part of the GEA group, specializes in screw compressors for industrial refrigeration applications, including those using ammonia as a refrigerant. Their compressors are designed for high reliability and low maintenance.

These brands are recognized for their quality, reliability, and innovation in the field of refrigeration compressor technology, catering to various needs and applications across the industry.